Unleash your full productivity

Due to the ever-increasing complexity of product design, modern product manufacturing requires processes and techniques that ensure precision and accuracy. Therefore, development and innovation in manufacturing technology, especially the introduction of automation, has been subject to a boom.

CNC News

Alle anzeigen-

What can a twist drill drill? Can it drill thro...

The use of twist drills is directly related to the style and type. There are cobalt-containing stainless steel twist drills, parabolic deep-hole twist drills, gold-containing twist drills, titanium-plated twist...

What can a twist drill drill? Can it drill thro...

The use of twist drills is directly related to the style and type. There are cobalt-containing stainless steel twist drills, parabolic deep-hole twist drills, gold-containing twist drills, titanium-plated twist...

-

What is the Taper Shank Twist Drill?

The tapered shank twist drill is the most widely used hole processing tool, usually with a diameter ranging from 0.25 to 80 mm. It is mainly composed of a working...

What is the Taper Shank Twist Drill?

The tapered shank twist drill is the most widely used hole processing tool, usually with a diameter ranging from 0.25 to 80 mm. It is mainly composed of a working...

-

What Is BTA Drill Bit?

BTA drilling is a deep hole drilling process that uses specialized drilling tools on long drill pipes to drill deep holes in metal, ranging from holes with a diameter of...

What Is BTA Drill Bit?

BTA drilling is a deep hole drilling process that uses specialized drilling tools on long drill pipes to drill deep holes in metal, ranging from holes with a diameter of...

Hot Selling

-

BTA Deep Hole Drill Bit Drill Head For Holemaking Tools

Normaler Preis Von $105.11 USDNormaler PreisStückpreis / pro$150.00 USDVerkaufspreis Von $105.11 USDSale -

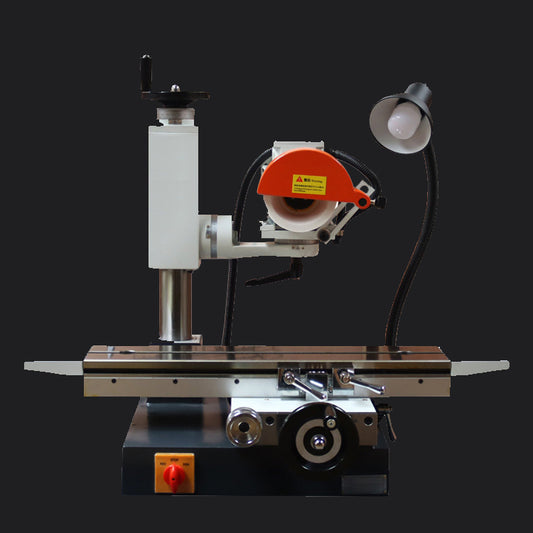

GD-600S Grinding Machine For CNC Cutting Tools

Normaler Preis $1,050.00 USDNormaler PreisStückpreis / pro$1,400.00 USDVerkaufspreis $1,050.00 USDSale -

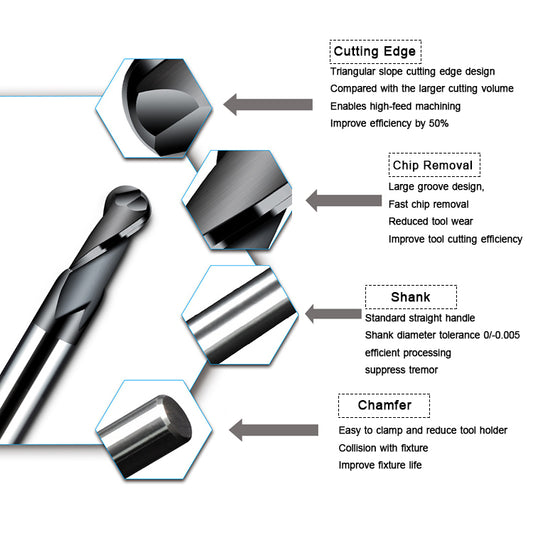

HRC45 Carbide Tungsten 2 Flute Ball Nose End Mill For CNC Machine

Normaler Preis Von $1.39 USDNormaler PreisStückpreis / pro$4.50 USDVerkaufspreis Von $1.39 USDSale -

HRC55 Carbide Tungsten 2 Flute Ball Nose End Mill

Normaler Preis Von $2.87 USDNormaler PreisStückpreis / pro$4.50 USDVerkaufspreis Von $2.87 USDSale

Why choose us?

-

Humanized Customization

The experienced scientific research teamis committed to providing customers withresearch and development.production andactual programming solutions for tools usedin deep hole machining

-

Factory Quality Assurance

Since 2006, we have established a firm foothold in thedomestic market and have won many customers in Southeast Asia, the United States and other places. The company hasalso introduced foreign advanced technology and equipmentand is committed to maintaining close cooperation with machining centers around the world.

-

After-sales support

Due to the complexity of large-scale deep holemachining, we are also equipped with a strong after-sales service team to provide one-stop OEM service for deep hole tool machining solutions